Bolting Services

Home /

Bolting Services

Controlled Bolting

A bolted Joint reviews more than one challenge which includes Temperature versions, Stress, Vibration, Corrosion and different demanding situations. Consequently for any Joint meeting on pressurized machine, bolting and piping to be leak-free, correct bolt tightening is vital.

Massive complicated machinery and pipelines are held collectively by using easy bolts. Bolted Joints should provide a hundred joint reliability as these are part of each vital utility

By replacing guide hand gear with managed bolting, manufacturing improves significantly. Controlled bolting makes use of calibrated, examined equipment and skilled operators who are skilled periodically. The operators follow precise processes and attain joint integrity.

Bolting Services

Especially dedicated crew is periodically trained and licensed to fulfill worldwide bolting requirements.

Our Services includes:

- Bolt Torquing Service

- Bolt Tensioning Service

- Cold Pipe Cutting

- Flange Facing

Bolting Methods

Clamping force is typically achieved by two methods:

- Torquing

- Tensioning

It is common for bolts to become slightly elongated. As a result of this stretch, the joint is clamped together. Stretching a bolt creates spring tension using Bolt Tensionless and Bolt Torque Wrenches.

However, each method differs from the other

The nut is lengthened using the torque method by applying twisting force. Direct stretching of the stud is used in the tensioning process.

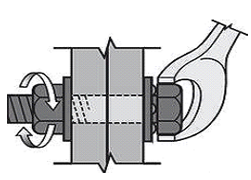

Torquing

Most Customers favour tensioning over Torquing for sensitive applications which require higher accuracy. To achieve preload, the bolt is directly stretched along its axial axis by tension.Mechanical effort to create torque is replaced with simple Hydraulic pressure.

One of the most popular forms to install fasteners is by appying torque.Frequently, a torque value is specified for a particular application, and this torque value is obtained using a calibrated torque wrench.Also,a torque reading does not immediately reflect the bolt tension. Only indirectly may tension be determined from a torque reading.

Bolting Methods

Torquing

- Accuracy: Less Accurate than hydraulic tensioners

- Cost of Operation: Economical

- Ease of Operation: Simple to use, Works with normal bolt length

- Method of Stretching: Stretching is done by turning the nut – Indirect Method

- Applications: Used on all Sizes

- Reliability: Less reliable than tensioners, Uneven bolt load can occur; Friction factors affect the load, lesser possibility of Gasket damage.

- Equipment: Pump pressure of 10,000 psi is used

- Speed of Operation: Slower compared to Tensioning

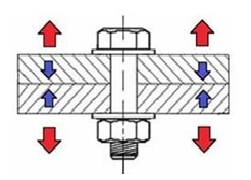

Tensioning

- Accuracy: High Accurate than hydraulic tensioners

- Cost of Operation: More Expensive

- Ease of Operation: More technical expertise and additional bolt length is required

- Method of Stretching: Stretching is done by pulling the stud – Direct Method

- Applications: More often used on large bolts, Suitable for critical applications

- Reliability: More reliable, Bolt load is distributed more uniformly, Direct tensioning, Possibility of over compression of Gasket material.

- Equipment: Pump pressure of 25,000 psi is used

- Speed of Operation: Faster, as more bolts are pulled simultaneously.